The oilfield has historically been a place where brawny men, and mighty machines came together to bore holes deeply into the earth to wrest stores of oil and gas from the depths. This model, which developed over many decades of exploration and production activity carried huge costs, particularly as the focus of this activity moved into more and more inaccessible regions. The current oil crash and resultant industry consolidation, began in 2014, and continues to this day. Downturns are nothing new to this industry. The difference this time is the longevity and severity of this downturn has kept any real recovery from taking place in the broader industry. Companies have been forced into retrenchment after retrenchment in both the operating and service industry.

Rystad As the Rystad graphic above illustrates, capital has fled the E&P sector, due in large part to uncertainties about oil and gas prices and a shift toward renewable forms of energy.

Energy giant, Halliburton, (NYSE: Hal) reported results last week, and largely surprised analysts with their ability to cut costs and generate Free Cash Flow, in a constantly shrinking market. What escaped much notice in the conference call after the earnings release, was the direction that Halliburton CEO, Jeff Miller sees shaping up for the oilfield of the future. In this article we will take a look at some of the key manifestations of this change.

A smaller industry footprint to producing increasing amounts of oil and gas

Miller pointed out in the call that the cuts are permanent reductions in employee count and facilities infrastructure.

“Halliburton is charting a fundamentally different course. The growth in digital technologies, the position of strength in the returns for our shareholders. We believe that the strategic actions we are taking today will further boost our earnings power and free cash flow generation ability as we power into and win the eventual recovery.”

Source To fully understand the implication of Miller’s comments it is important to combine the reduction in capex supplied to the industry with the continuing need for oil and gas well into this century.

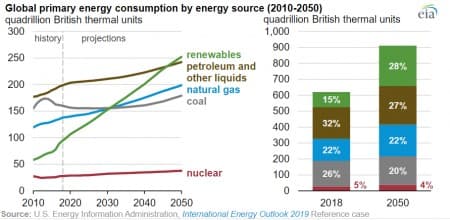

EIA This graphic from the EIA shows that global energy growth to mi d-century and beyond, will primarily derive from continued production of oil and gas.

d-century and beyond, will primarily derive from continued production of oil and gas.

The story of how companies like Halliburton will achieve these energy production goals, while at the same time having less and less money and resources to employ in this effort is the focus of the rest of this article.

Technology driving the future

Technology seems to gravitate to the oilfield. Doing more with less has always been in the background as the industry responded to ever increasing markets with large explosions of capex. Those days are gone as we have noted, and increasingly what would have been big capex solutions are moving to smarter, more flexible components that deliver value while packing in profits to the supplier. You will also see more joint ventures with participants each bring key attributes to increasingly digital solutions.

Here are some examples noted in the Halliburton, second quarter conference call-

- Halliburton and TechnipFMC introduced Odassea™, the world’s first distributed acoustic sensing solution for subsea wells. The technology platform enables operators to execute intervention-less seismic imaging and reservoir diagnostics to reduce total cost of ownership while improving reservoir knowledge. Halliburton provides the fiber optic sensing technology, completions and analysis for reservoir diagnostics. TechnipFMC provides the optical connectivity from the topside to the completions. The Odassea platform strengthens digital capabilities in subsea reservoir monitoring and production optimization.

“Interventionless” is the key term I’ve bolded in the above statement. Interventions are expensive shutdowns of producing wells that often require a rig-a big expensive piece of machinery. They can be done rigless, but that’s an outlier. In this case the company is describing smart equipment that will remotely engineered solutions can fix itself.

- Halliburton, and Microsoft announced a five-year strategic agreement to advance Halliburton’s digital capabilities in Microsoft Azure. Under the agreement, Halliburton will complete the move to cloud-based digital platforms and strengthen our customer offerings by enhancing real-time platforms for expanded remote operations; improving analytics capability utilizing machine learning and artificial intelligence; and accelerating the deployment of new technology and applications for overall system reliability and security.

How will this work?

Researchers and engineers from both companies will leverage and optimize Microsoft technologies in machine learning, augmented reality (AR), user interactions and Industrial Internet of Things, as well as Azure’s high-performant infrastructure and built-in computing capabilities to deliver tightly integrated solutions across the energy value chain. Areas of collaboration include

- Applying deep learning to reservoir characterization,

- Modeling and simulation,

- Building domain-specific visualization for mixed reality,

- Creating highly interactive applications,

- Fueling the digitalization of E&P assets.

As a first step in the alliance, Halliburton has made its DecisionSpace® 365 available on Azure, enabling real-time data streaming from IoT edge devices in oilfields and the ability to apply deep-learning models to optimize drilling and production to lower costs for customers. Using the power of DecisionSpace® on Azure, big computing and predictive deep-learning algorithms will help optimize field assets and enable next-generation exploration and deep-earth models by using software to fill gaps in sensor data, while reducing the number of steps and time required to render models.

Nagaraj Srinivasan, senior vice president of Landmark and Halliburton Digital Solutions, commented in a recent press release from Microsoft-

“Halliburton is at the forefront of the digital transformation occurring in the E&P industry. We believe open architecture and community-based innovation are necessary to drive this fundamental change and we’re proud to work closely with an industry leader like Microsoft to deliver tailored E&P digital business solutions to our customers across the globe.”

- Halliburton recently launched DynaTrac™ Real-Time Wireless Depth Correlation System, a new technology that reduces uncertainty and saves rig time by enabling operators to accurately position packers, perforating guns and the bottom-hole assembly without running wireline or moving the work string.

Depth correlation is one of the most problematic scenarios in the oilfield. I can remember being shut down for hours as wireline was rigged up to confirm firing depth for guns (Hey, in the shallow GoM where the sand interval between shale strata can be 5-feet total), prior to perforating. Or is my packer-a zonal isolation device, where it needs to be to land out my completion string? Questions like this have to be answered, and Halliburton is doing this without the mechanical risk-you don’t always make it out the hole with everything that goes in. In the oilfield the term “fishing trip,” doesn’t have pleasant connotations.

- Finally, Halliburton has introduced SPECTRUM® e-IP, the industry’s first electrically operated inflatable packer. It provides precision and reliability for the placement of selective treatments, such as acidizing, water shut off, sand consolidation, and remedial integrity. This is especially relevant in the current market conditions, to increase the well performance in existing assets. The platform is digitally enabled to provide data acquisition, interpretation, and real-time control.

Mechanically set packers run on pipe or wireline have been the standard for the industry for decades, as changing the circulation path was also mechanical process. Pushing a button to set, reset or shift this tool has been a dream of the industry. Not having to move the tool is a critical step change improvement, capable of saving 10’s of thousands of hours of lost rig time globally.

Your takeaway

The oilfield will be a smaller place in the decades to come. Companies like Halliburton will have to adapt from the old model of spending huge sums of capex and hiring tens of thousands of employees. The model of the future will be one where AI leverages the power of fewer employees to control the production of smarter machines, and hopefully generating improved returns on capital invested.

Halliburton is trading higher in the days after their earnings release!

By David Messler for Oilprice.com